- CNC MACHINE AUTOMATION

- DRILLING & BEVELING

- HYPERTHERM PLASMA CUTTING MACHINE

- OVEN

- OXYFUEL EQUIPMENT

- ROBOTIC WELDING SYSTEM

- SAFETY

- SOFTWARE

- WELDING CONSUMABLES AND ACCESSORIES

- WELDING MACHINE

- WELLNIT

Amcoweld (M) Sdn Bhd

Head Off : Setia Business Park II, 16, Jalan Perniagaan Setia 7, Taman Perniagaan Setia, 81100 Johor Bahru, Johor, Malaysia.

+607-5559555

+607-5559666

+6019-773 1310

+60197731310

KL Off : NO. 7, Jalan Sungai Beting 3/KU3, Off Jalan Sungai Putus, 42100 Klang, Selangor, Malaysia.

+603-3291 1818

kl@amcoweld.com.myAmcoweld Inc Pte. Ltd. Blk 1005 Eunos Ave 7, #01-06/08, Singapore 409576.

+65 6742 9595

+65 6749 9595

amcoweld@singnet.com.sgPt. Amcoweld Indonesia Komplek Pertokoan Dian Centre, Block C No.12A, Batam, Indonesia.

+62 7784 58286

+62 7784 58495

amcoweld_indo@yahoo.comAmcotech Vietnam Co., Ltd 37 Ton Duc Thang Street, 19th floor Suite 1901, Saigon, Trade Center, District 1., Ho Chi Minh City, Vietnam.

+84 8 2220 2970

+84 8 2220 2971

sales@amcotech.com.sgHYPERTHERM HPR800XD

| Previous | 1 / 2 | Next |

Hypertherm HyPerformance HPR800XD

Overview

Hypertherm is ISO9001:2000 certified

The HPR800XD extends the versatility of HyPerformance Plasma to providethe most expansive process range and thickest stainless steel andaluminum cutting capacity available on the market

Hypertherm has spent more than four decades developing over 75 patented plasma technologies to providecustomers with exceptional performance they can count on. With thousands of HyPerformance Plasma systemssold around the world, the HPR product family has become the plasma system of choice for customers whodemand the most consistent cut quality, highest productivity, lowest operating cost and unmatched reliability.

Thick stainless steel and aluminum cutting capacity

Patent pending PowerPierce™ technology enables 75 mm (3″) production piercing capacity and 160 mm (6¼”) severance of stainless steel and aluminum to meet the most demanding cutting requirements.

Expansive process range delivers extended versatility

Building on the HPR400XD, the HPR800XD uses all HyPerformance Plasma processes from 30 to 400 amps for marking, beveling and cutting mild steel, stainless steel and aluminum. This versatility is extended to thick stainless steel and aluminum, up to 800 amps.

Maximized productivity and improved profitability

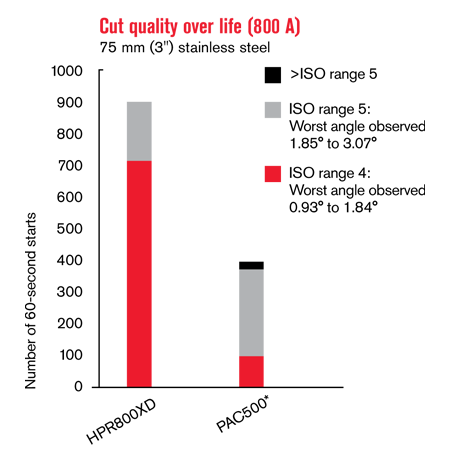

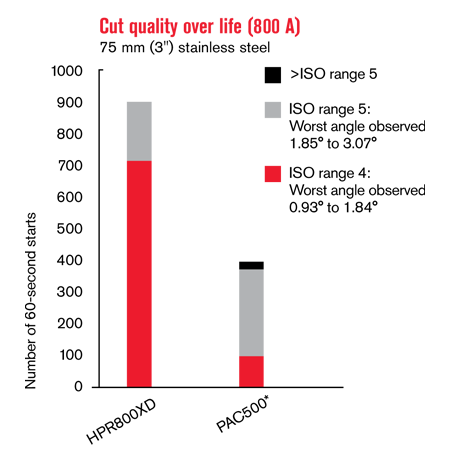

Patented LongLife® and HyDefinition® technologies deliver more consistent cut quality over a longer period of time. HyPerformance Plasma combines this consistency with fast cutting speeds and quick changeovers to maximize productivity and improve profitability.

Unmatched reliability

Extensive testing, backed by more than four decades of experience, guarantees the Hypertherm quality you can count on.

Specifications

* F5 = 5% H , 95% N2

** H35 = 35% H , 65% Ar

Specifications

* F5 = 5% H , 95% N2

** H35 = 35% H , 65% Ar

| Per power supply | Chiller | |||

| Input voltages | VAC | Hz | Amps | Amps |

| 200/208 | 50/60 | 262/252 | 30 | |

| 220 | 50/60 | 238 | 30 | |

| 240 | 60 | 219 | 30 | |

| 380 | 50/60 | 138 | 20 | |

| 400 | 50/60 | 131 | 20 | |

| 440 | 50/60 | 120 | 20 | |

| 480 | 60 | 110 | 15 | |

| 600 | 60 | 88 | 12 |

| Output voltage | 200 VDC |

| Output current | 800 A |

| Duty cycle | 100% at 40°C (104°F) at 160kW |

| Maximum OCV | 360 VDC |

| Dimensions per power supply | 118 cm (46.4'') H / 88 cm (34.7'') W / 126 cm (49.7'') L |

| Chiller | 170.2 cm (67'') H / 87.6 c (34.5'') W / 137.2 cm (54'') L |

| Weight per power supply | 851 kg (1877 lbs) |

| Chiller | 449kg (990 lbs) |

| Plasma gas | O2 / N2 / F5* / H35** / Air / Ar |

| Shield gas | N2 / O2 / Air / Ar |

| Gas pressure |

8.3 bar (120 psi) Manual gas console 8.0 bar (115 psi) Automatic gas console |

Hypertherm is ISO9001:2000 certified

Hypertherm full-system warranty – complete coverage for two years on all system components and one year on the torch and leads.

Operating Data

Operating Data

| Material | Current (amps) | Thickness (mm) | Approximate cutting speed (mm/min.) | Thickness (inches) | Approximate cutting speed (ipm) |

|---|---|---|---|---|---|

| Mild steel | 30 | 0.5 | 5355 | .018 | 215 |

| O2 plasma | 30 | 3 | 1160 | .135 | 40 |

| O2 shield | 30 | 6 | 665 | 1⁄4 | 25 |

| O2 plasma | 80† | 3 | 6145 | .135 | 180 |

| O2 shield | 80† | 6 | 3045 | 1⁄4 | 110 |

| O2 shield | 80† | 20 | 545 | 3⁄4 | 25 |

| O2 plasma | 130† | 6 | 4035 | 1⁄4 | 150 |

| Air shield | 130† | 10 | 2680 | 3⁄8 | 110 |

| Air shield | 130† | 25 | 550 | 1 | 20 |

| O2 plasma | 260† | 10 | 4440 | 3/8 | 180 |

| Air shield | 260† | 20 | 2170 | 3/4 | 90 |

| Air shield | 260† | 64 | 195 | 2-1/2 | 8 |

| O2 plasma | 400† | 12 | 4430 | 1/2 | 170 |

| Air shield | 400† | 25 | 2210 | 1 | 85 |

| Air shield | 400† | 50 | 795 | 2 | 30 |

| Air shield | 400† | 80 | 180 | 3 | 10 |

| Stainless steel | 45 | 1 | 5740 | .036 | 240 |

| F5 plasma | 45 | 2.5 | 2510 | .105 | 90 |

| N2 shield | 45 | 6 | 845 | 1/4 | 30 |

| F5 plasma | 80 | 4 | 2180 | .135 | 105 |

| N2 shield | 80 | 6 | 1225 | 1/4 | 45 |

| N2 shield | 80 | 10 | 560 | 3/8 | 25 |

| H35 plasma | 130† | 10 | 980 | 3/8 | 40 |

| N2 shield | 130† | 12 | 820 | 1/2 | 30 |

| N2 shield | 130† | 25 | 260 | 1 | 10 |

| H35 plasma | 260† | 12 | 1710 | 1/2 | 65 |

| N2 shield | 260† | 20 | 1085 | 3/4 | 45 |

| N2 shield | 260† | 25 | 785 | 1 | 30 |

| H35 and N2 | 400† | 20 | 1810 | 3/4 | 75 |

| plasma | 400† | 40 | 720 | 1-1/2 | 30 |

| N2 shield | 400† | 80 | 190 | 3 | 10 |

| H35 and N2 | 600† | 40 | 721 | 1-1/2 | 29 |

| N2 shield | 600† | 60 | 492 | 2-1/2 | 16 |

| N2 shield | 100 | 187 | 4 | 7 | |

| N2 plasma | 600† | 40 | 970 | 1-1/2 | 40 |

| N2 shield | 600† | 60 | 434 | 2-1/2 | 16 |

| N2 shield | 80 | 305 | 3 | 12 | |

| H35 plasma | 800† | 75 | 464 | 3 | 18 |

| N2 shield | 800† | 125 | 155 | 5 | 6 |

| N2 shield | 160 | 100 | 6-1/4 | 4 | |

| Aluminum | 45 | 1.5 | 4420 | .048 | 220 |

| Air plasma | 45 | 4 | 2575 | .135 | 110 |

| Air shield | 45 | 6 | 1690 | 1/4 | 60 |

| H35 plasma | 130† | 12 | 1455 | 1/2 | 55 |

| N2 shield | 130† | 20 | 940 | 3/4 | 40 |

| N2 shield | 130† | 25 | 540 | 1 | 20 |

| H35 plasma | 260† | 12 | 5160 | 1/2 | 190 |

| N2 shield | 260† | 20 | 2230 | 3/4 | 90 |

| N2 shield | 260† | 50 | 390 | 2 | 14 |

| H35 plasma | 400† | 20 | 2420 | 3/4 | 100 |

| N2 shield | 400† | 40 | 1190 | 1-1/2 | 50 |

| N2 shield | 400† | 80 | 210 | 3 | 10 |

| H35 plasma | 600† | 50 | 1302 | 2 | 50 |

| N2 shield | 600† | 60 | 839 | 2-1/2 | 30 |

| N2 shield | 600† | 100 | 378 | 4 | 14 |

| N2 plasma | 600† | 50 | 1048 | 2 | 40 |

| N2 shield | 600† | 60 | 832 | 2-1/2 | 30 |

| N2 shield | 600† | 80 | 600 | 3 | 26 |

| H35 plasma | 800† | 75 | 907 | 3 | 35 |

| N2 shield | 800† | 160 | 179 | 6-1/4 | 7 |

Note: Take care in comparison: Competitors often show maximum cutting speeds , rather than speeds that deliver the best cuts , as shown above. Cut speeds listed above deliver best cut quality , but cut speeds can be up to 50% faster.

The operating data chart does not list all processes available for the HPR800XD. Please contact Hypertherm for more information.

† Consumables support up to 45° bevel capability.