- CNC MACHINE AUTOMATION

- DRILLING & BEVELING

- HYPERTHERM PLASMA CUTTING MACHINE

- OVEN

- OXYFUEL EQUIPMENT

- ROBOTIC WELDING SYSTEM

- SAFETY

- SOFTWARE

- WELDING CONSUMABLES AND ACCESSORIES

- WELDING MACHINE

- WELLNIT

Amcoweld (M) Sdn Bhd

Head Off : Setia Business Park II, 16, Jalan Perniagaan Setia 7, Taman Perniagaan Setia, 81100 Johor Bahru, Johor, Malaysia.

+607-5559555

+607-5559666

+6019-773 1310

+60197731310

KL Off : NO. 7, Jalan Sungai Beting 3/KU3, Off Jalan Sungai Putus, 42100 Klang, Selangor, Malaysia.

+603-3291 1818

kl@amcoweld.com.myAmcoweld Inc Pte. Ltd. Blk 1005 Eunos Ave 7, #01-06/08, Singapore 409576.

+65 6742 9595

+65 6749 9595

amcoweld@singnet.com.sgPt. Amcoweld Indonesia Komplek Pertokoan Dian Centre, Block C No.12A, Batam, Indonesia.

+62 7784 58286

+62 7784 58495

amcoweld_indo@yahoo.comAmcotech Vietnam Co., Ltd 37 Ton Duc Thang Street, 19th floor Suite 1901, Saigon, Trade Center, District 1., Ho Chi Minh City, Vietnam.

+84 8 2220 2970

+84 8 2220 2971

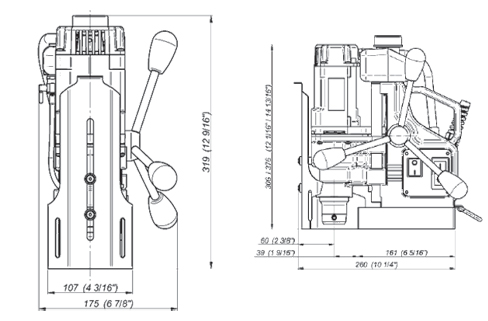

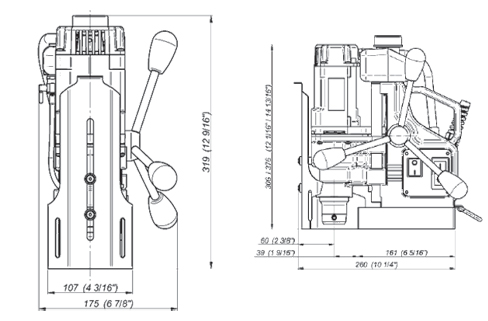

sales@amcotech.com.sgPRO 36 Compact Mag Drill

| Previous | 11 / 12 | Next |

PRO 36

Overview

The most compact machine designed by Promotech, and one of the smallest units in the world. Superior features: ultra lightweight, easy handling and maintenance free rail guide system. PRO 36 is equipped with the latest generation of electromagnetic energy saving base (ESB) with magnetic field shape control system (MFSC) and magnetic power adhesion control module (MPAC), which detects adhesive force of electromagnetic base and protects both the machine and the operator from work on too thin workpiece.

It includes also motor overload protection system.

Technical Specification

The most compact machine designed by Promotech, and one of the smallest units in the world. Superior features: ultra lightweight, easy handling and maintenance free rail guide system. PRO 36 is equipped with the latest generation of electromagnetic energy saving base (ESB) with magnetic field shape control system (MFSC) and magnetic power adhesion control module (MPAC), which detects adhesive force of electromagnetic base and protects both the machine and the operator from work on too thin workpiece.

It includes also motor overload protection system.

Technical Specification

| Tool holder | 19 mm (3/4'') Weldon |

| Milling Cutter (Core drill) O | max 36 mm (1 3/8'') |

| Countersinking O | max 40 mm (1 9/16'') |

| Stroke | 70 mm (2 3/4'') |

| Max depth of cut | 51 mm (2'') |

| Voltage | 115V/60Hz or 230V/50 Hz |

| Power consumption [W] | 1000 |

| Motor Power [W] | 920 |

| Speed [rpm] | 350 |

| Overload protection |

yes – 115V/60Hz no – 230V/50 Hz |

| MPAC (Magnetic Power Adhesion Control) | yes |

| MFSC (Magnetic Field Shape Control ) | yes |

| ESB (Energy Saving Base) | yes |

| Magnetic clamping force [N](25mm/Ra=1.25) | 9500 |

| Magnet Base Dimensions |

80 x 160 x 36.5 [mm] 3-1/8 x 6 -5/16 x 1 -7/16 [''] |

| Min. Workpiece Thickness | 6 mm (1/4'') |

| Weight | 10 kg |